Close

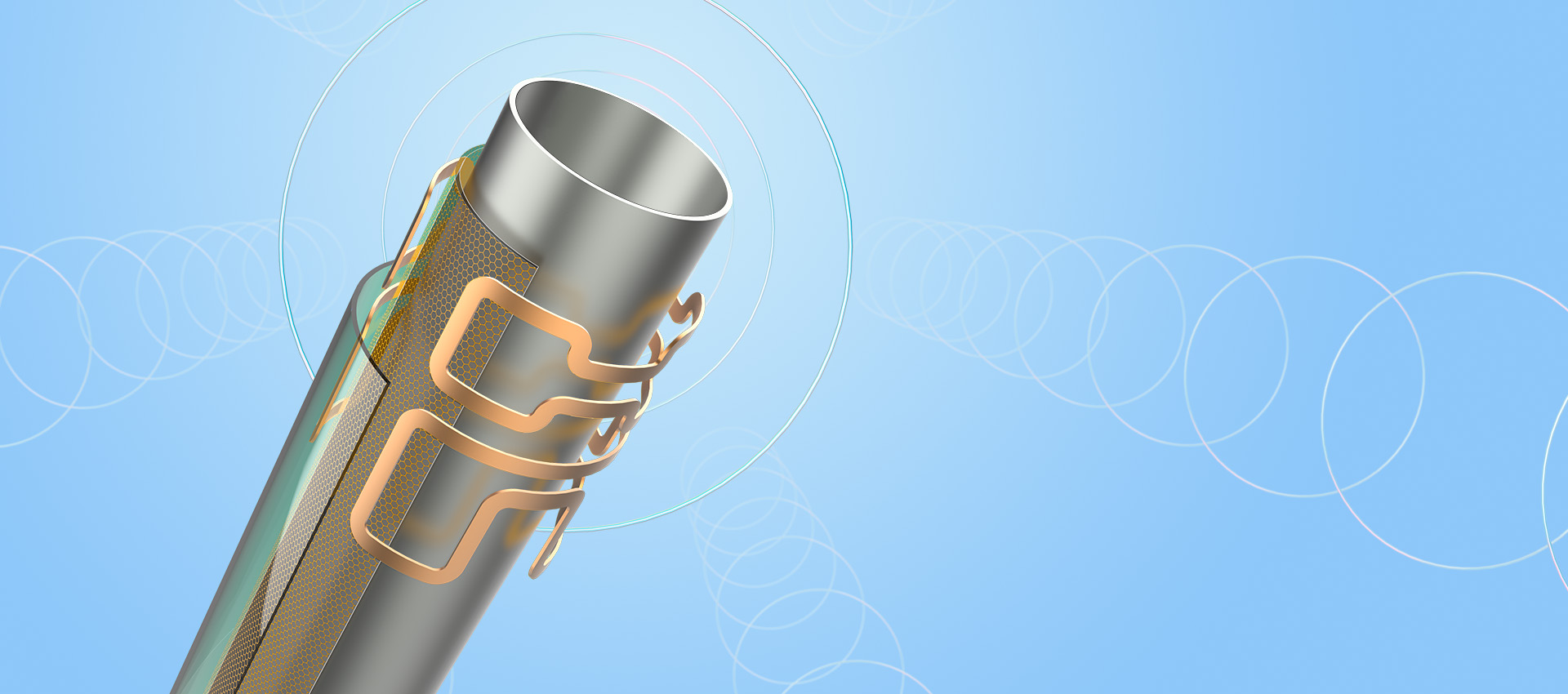

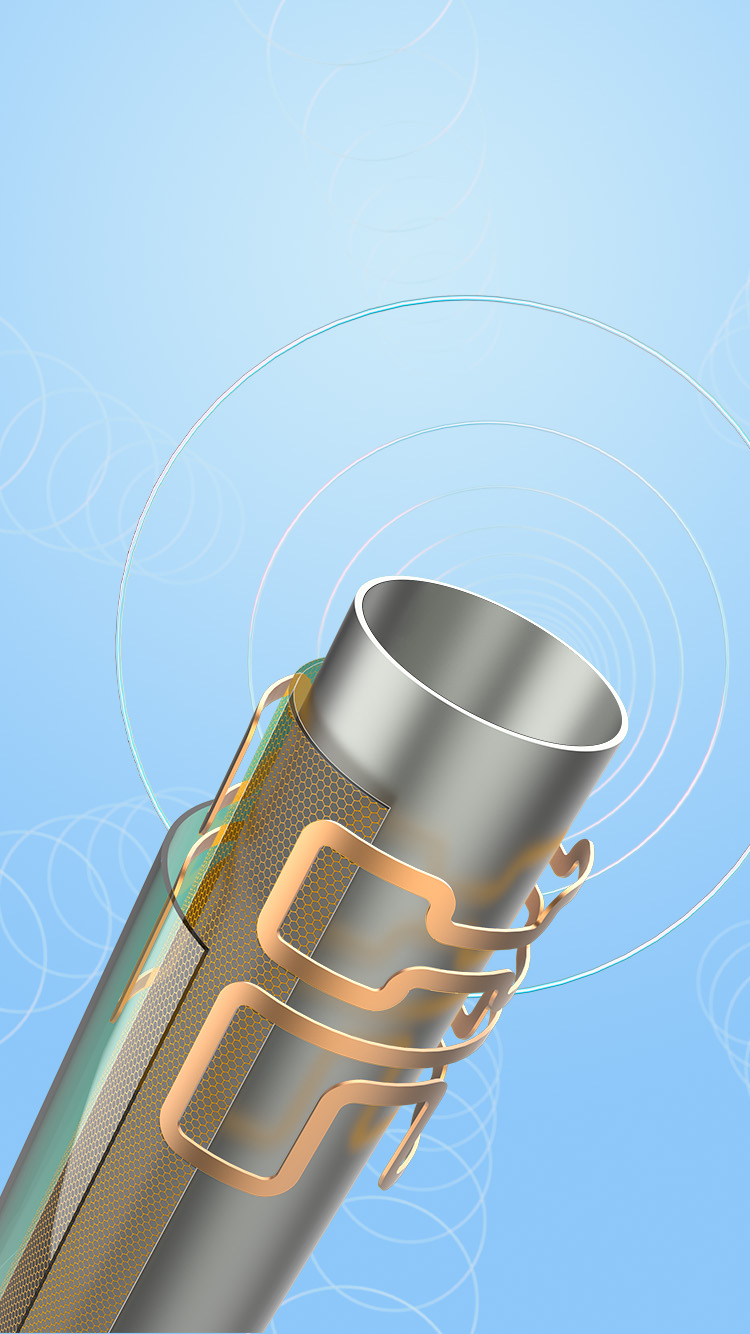

After repeated verification, the glaze material suitable

for the surface of the heater has been carefully selected,

Combined with a micro-nano structure, the adhesion

of soot and cleaning frequency can be greatly reduced.

The advanced low temperature co-firing technology

is used to realize miniaturized wiring. According to

the conductive properties of the slurry, the materials

and design of the heater are optimized, and the heating

film accurately covers the working area to maximize

the energy efficiency.

Metex's replaceable heater technology accurately identifies the characteristics of various heaters to deliver sensational multi-tastes and to achieve quick replacement and usage, bringing a joyful experience.

Adopting a new Heat Surround Comfort system,

combined with advanced CAE simulation to optimize

the temperature gradient of the heater, makes the

temperature field more stable and uniform,

which will thoroughly roast the medium and release

aroma molecules, bringing a consistent taste.

The new generation of 4-layer composite structure, equipped with the industry's original thick film printing process, which greatly shortens the temperature rise speed, comprehensively improves the temperature control accuracy and consistency, and brings high satisfaction.

Smart Tech is the core of Metex to reduce the energy

consumption of peripheral heating. It integrates

the unique material characteristics of heater, heater

transfer and insulation design, and the power system,

continuously analyzes and optimizes performance,

and stimulates the most effective substances

with the least energy consumption.

360-degree heating medium in a circular

design, meticulously considering every angle.

It leaves no residue or dirt, ensuring

exceptionally low cleaning frequency

and preventing the development of

odors that could impact the taste.

After repeated physical test, chemical analysis,

and safety assessment, combined with

composite material layers and temperature

control technology, the emission of

harmful substances, such as heavy

metals, aldehydes, ketones, hydroxyls

groups in the atomized medium has

been significantly reduced The overall

safety and reliability have been greatly improved.