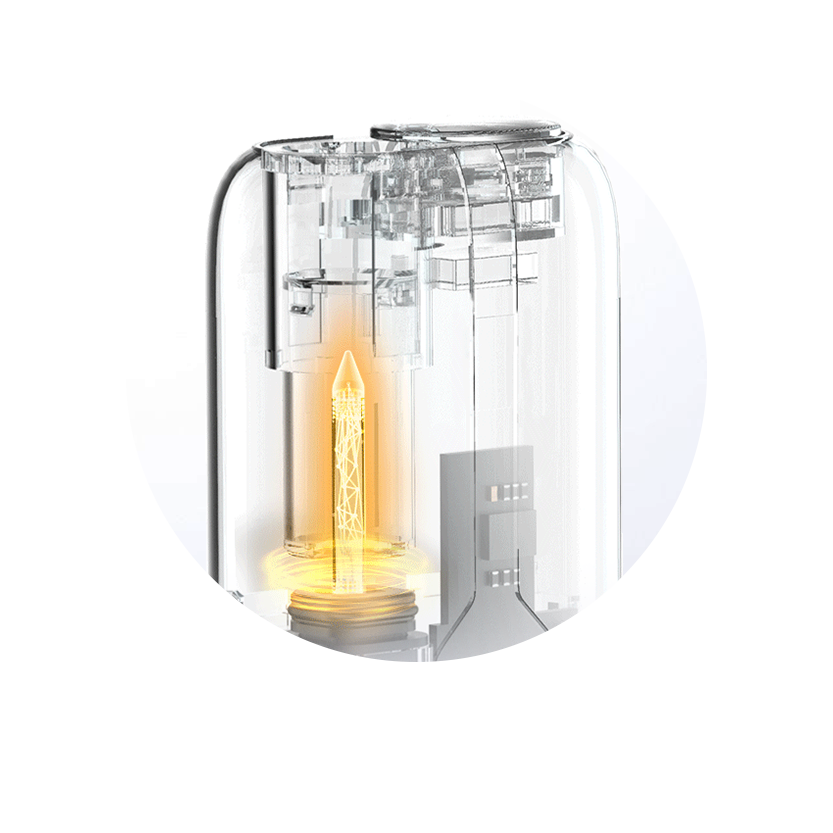

Resistance Heating

Powered by advanced structural design and multi-field temperature control, we bring an powerful burst and an extremely consistent taste. Our technology can significantly reduce the energy consumption by enhancing the electrical control performance and the thermal conversion rate.

Resistance Center Heating

-

Fast Ramp-up

Fast Ramp-up -

Low Energy Consumption

Low Energy Consumption -

Easy to clean

Easy to clean

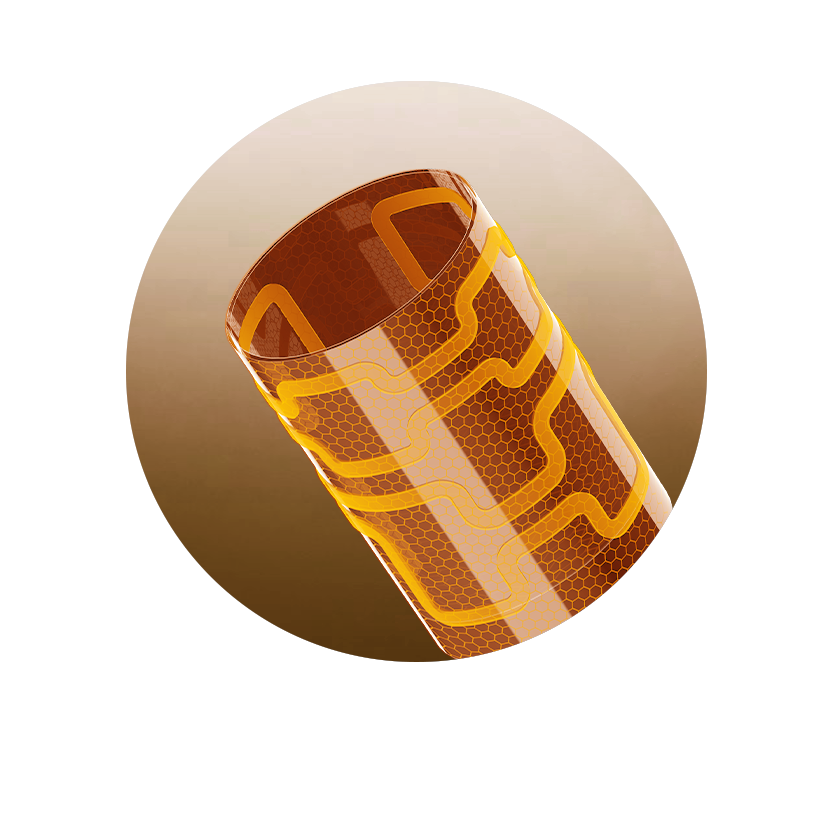

Self-Developed Low Temperature Co-firing Technology, Empower Your Usage

The advanced low temperature co-firing technology is used to realize miniaturized wiring. According to the conductive properties of the slurry, the materials and design of the heater are optimized, and the heating film accurately covers the working area to maximize the energy efficiency.

New Process Structure, Less Cleaning

After repeated verification, the glaze material suitable for the surface of the heater has been carefully selected. Combined with a micro-nano structure, the adhesion of soot and cleaning frequency can be greatly reduced.

Resistance Round Heating

-

Uniform Heat Transfer

Uniform Heat Transfer -

Precise Temperature Control

Precise Temperature Control -

Zero Cleaning

Zero Cleaning

-

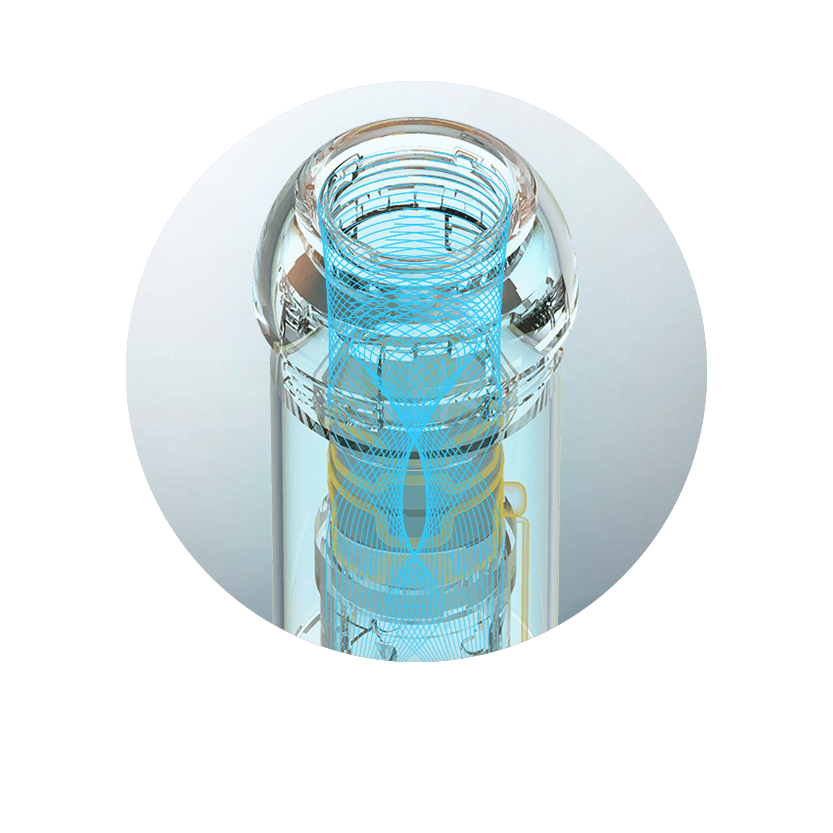

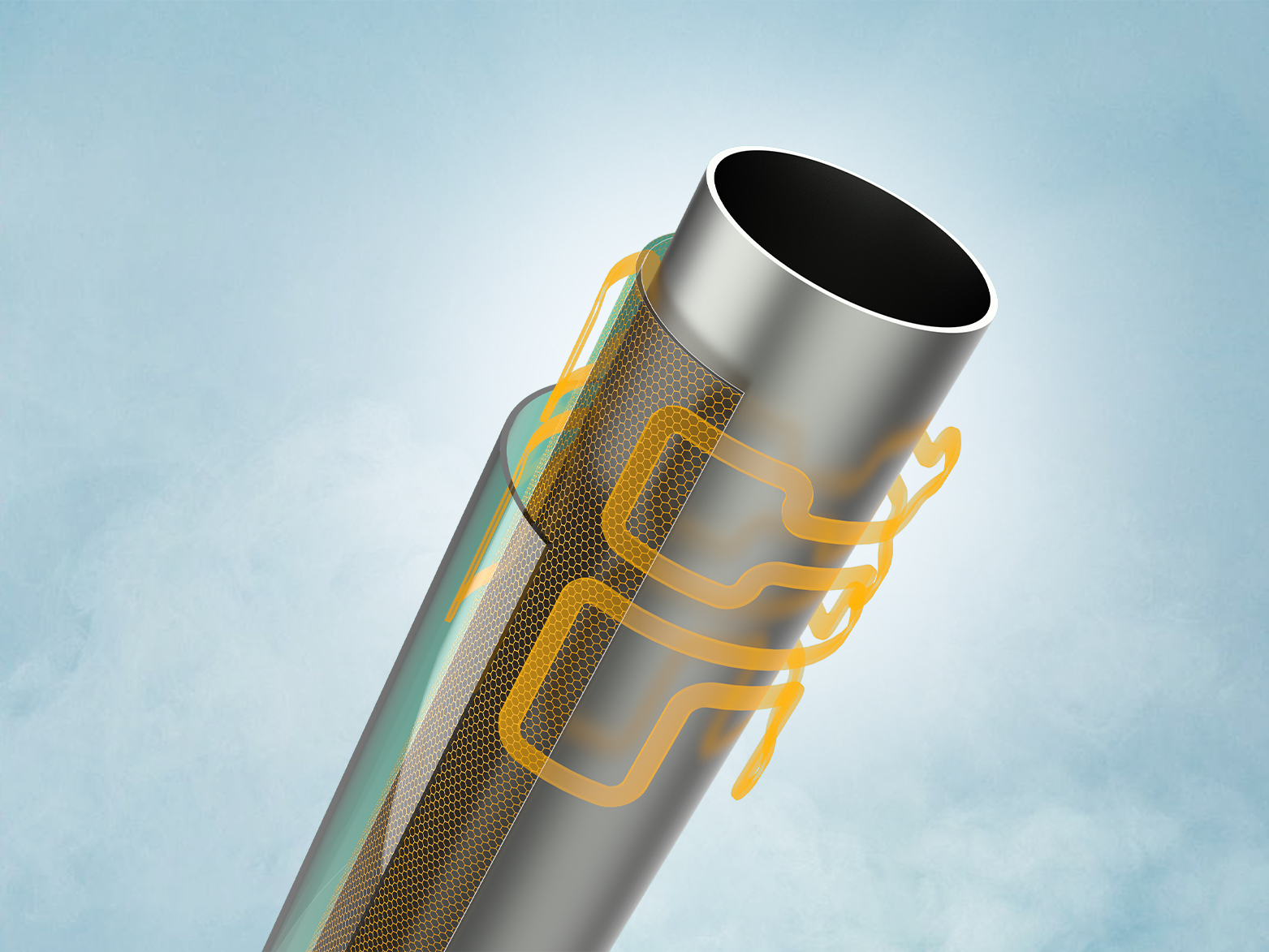

Self-Developed High-Precision Thick Film Process, Release Performance

The new generation of multi-layer composite structure, equipped with the industry's original thick film printing process, which greatly shortens the temperature rise speed, comprehensively improves the temperature control accuracy and consistency, and brings high satisfaction. -

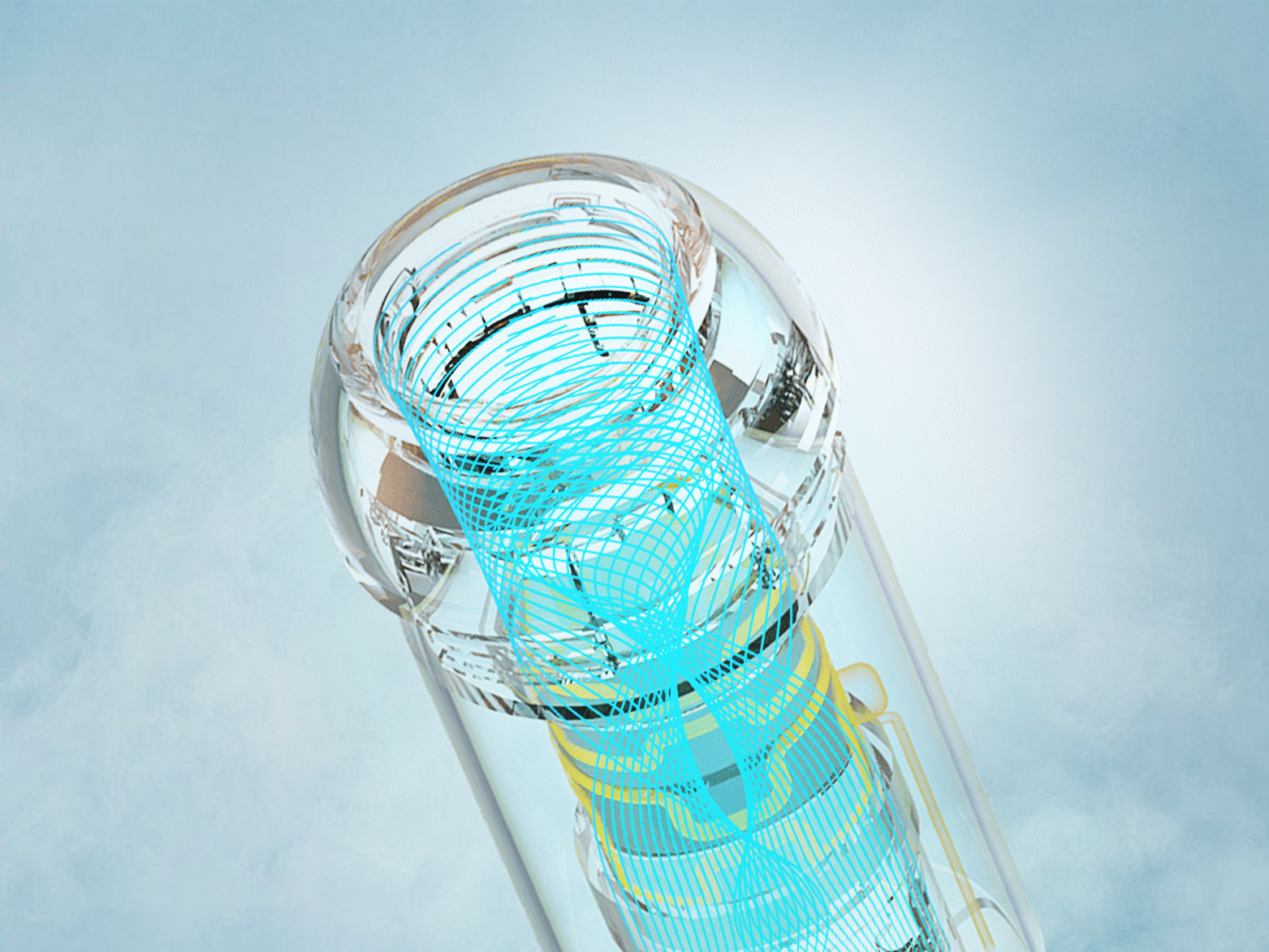

Easy to Clean, Restore Real Taste

360-degree heating medium in a circular design, meticulously considering every angle. It leaves no residue or dirt, ensuring exceptionally low cleaning frequency and preventing the development of odors that could impact the taste.